Description

MODULE DESCRIPTION:

A CDI / High Energy Ignition conversion module that is triggered with the standard OEM breaker-points that exist in older ignition systems.

A High-Energy CDI ignition provides; Easier starting, better idle, better throttle response, reduces plug fouling and overall better performance.

Perfect for older 1-2 cylinder sleds, ATV, 2 & 4-stroke motorcycles, garden-tractors, go-carts and even outboards. Advantage is a much higher spark energy delivered to the spark-plug.

The feedback on the modules has been all positive and many can’t believe the difference it made!

INSTALLATION:

The OEM points & condenser are retained (see wire disconnection).

The module requires the elimination of the OEM magneto source coil wire & Condenser from the breaker-points terminal. (see “X” marking in sketch below of magneto & condenser wires that requires disconnection)

This will require removal of the flywheel to access the magneto wire junction.

Module requires a CDI ignition coil (purchased separately) to replace existing points/condenser type coil. Connect CDI-type coil wire to module Orange wire.

Remove recoil to access flywheel. Once flywheel is removed, locate the magneto source wire (upper coil in pictures) that junctions to the connection of the points/condenser. Simply de-solder or clip the wire from the magneto coil at the condenser junction (see note below). Insulate & isolate the loose hanging wire from any contact by using heat-shrink tubing. Magneto coil will remain active, even though disconnected. Isolate by tucking wire away from any rotating components or points cam so no interference with moving parts.

Note: The condenser is not necessary for the module to function, so does not need to remain connected, so it is suggested to disconnect condenser from points junction when the magneto source coil is disconnected. We found a case where allowing the condenser to remain caused a no-spark issue. It may have been a failed condenser, since our SM292 Yamaha works fine with the condenser remaining connected. However, since the condenser is absolutely not needed for the module, it is best to also remove it’s connection from the points junction as well, potentially saving a second disassembly to remove if an issue occurs .

Below is a video of the initial testing of the SM292 Yamaha with the Fireplug CDI module connected (prior to permanent installation).

OUR SM292 YAMAHA TEST SLED INSTALLATION

SM292

1-CYL FIREPLUG CDI CONVERSION MODULE INSTALLATION

Disconnecting the magneto source coil wire eliminates the high-voltage that was previously needed to energize & spark the coil when the points opened. The CDI module cannot tolerate the high-voltage from the coil (internal damage will result), therefore the magneto coil wire must be disconnected as discussed above. The condenser is no longer needed, since there is no points arcing with the module. Leaving the condenser has caused some issues on some installations, and no issues on others. Better to remove the condenser wire attachment from points as well, since not needed for the module input.

Disconnecting this coil also significantly reduces the current through the breaker-points, eliminating point spark, pitting and the constant re-adjustment required with conventional breaker-point systems. The points contacts will last much longer with minimal maintenance. Due to the module reduces the switching current across the breaker-points to about 1 milliamp (0.001 amp) with the magneto source coil disconnected. The lifetime of the points will then be more related to their mechanical limitations, not electrical.

Module requires a CDI ignition coil (purchased separately) to replace existing points/condenser type coil. Connect CDI-type coil wire to module Orange wire.

With Magneto source coils disconnected and flywheel & recoil replaced. Connect existing breaker-points / Coil wire to TRIG INPUT wire on module. Connect the Orange wire from the module to the new CDI coil. Module must be mounted to chassis / grounded & bolted down. Connect a switched 12V battery Power wire to the RED module wire, and Ground the Black wire. Battery ground should also be connected to the Chassis for a common ground.

A small 12V battery is required for Module power. If a lighting coil & voltage regulator exists, the battery may be connected by using a diode in series that would allow charging of the battery from the existing lighting circuitry.

If the lighting is connected to recharge the battery, the module power draw is minimized, mainly used for initial starting, then the 12V lighting system will supplement power to the battery & module. Typical power draw is about .5-AMPS (6W) at cruising RPM and under 1.5 AMPS (17W) at 10,000RPM. The common 12V batteries used in electric start snowmobiles or motorcycles work perfectly and easily stay charged by the existing alternator / charging system. Battery connection options are detailed if no access to a 12V lighting system wiring exists.

A separate battery pack can also be used, and remain isolated from any of the existing snowmobile wiring if desired. Other rechargeable 12V battery packs are also an option, since the Module minimal current draw. Typically a small 12V @ 5000mAhr battery will provide over 8hrs of run time until recharging is required. Module must be bolted to the chassis so the module is grounded through the mounting bolts, so engine & module have common ground. Module has a RED power LED indicator that flashed 2X on power up, indicating it’s operating.

What is required:

POINTS/CONDENSER IGNITION SYSTEM:

Single Cyl / Twin-Cylinder engine with conventional points/condenser type ignition system (2 or 4-cycle) (disconnect magneto source coil wire)

12v BATTERY POWER:

A 12V battery is necessary for DC power supplied to the module.

If system has Electric-Start, the existing 12V battery can be used for Module power. Connect the RED wire to a separate switch or existing switched power that can disconnect the battery power to the module when not in use. This eliminates the module from draining battery power when engine is not running.

Maximum current draw of the module is about 1.4 AMPS (17W) at wide open throttle, and less than 0.5A at cruising speeds.

Most motorcycle batteries are 6-12A/hr and Garden tractor batteries are 12-30A/hr, allowing the module to last a minimum of 3hrs on a motorcycle battery , or as long as 20 hrs on a garden tractor battery. Duration will be longer if with lesser RPM’s.

For our testing, we are using the commonly available UB1280 – 12 Volt 8Ah Capacity – F1 Terminal SLA / AGM REPLACEMENT BATTERY. These can be found relatively cheap (under $20) on Ebay. 8Ah will easily last all day of riding on a single charge.

NOTE: We have added a small diode to route the lighting current to charge / supplement the battery power usage. Had it like this for a few months now and have yet to charge the battery. Still have some testing to do, but this seems to be working on our SM292. (see pic below)

CDI-TYPE IGNITION COIL:

The Points/Condenser type coil must be replaced with a CDI type ignition coil. Almost anything will work from an existing snowmobile or motorcycle that has a CDI type ignition system. Typical suggestions for available coils are listed below. We’ve found Parts Reloaded (click on link) usually has stock:

Single cylinder Coils: 72-76 Yamaha SRX, GPX and Exciter or Kohler / JD / RUPP coils from Prestolite system, or see part# below.

EXAMPLE: 01-143-16 / External Ignition Coil – Yamaha Snowmobile (085-2)

Twin cylinders Coils: 77~90’s Yamaha Exciter, Phazer, Enticer VMAX or Polaris TX/TXL/TXC Siamese type coils. Also some coils from Ski- Doo that used Nippondenso CDI’s may work, or see part number below.

EXAMPLE: YAMAHA 01-143-14 External Ignition Coil – (085-3) or Arctic-Cat 01-143-120

PARTS RELOADED HAS THE COILS LISTED ABOVE

KILL-SWITCH : The factory kill-switch/key-switch can be retained as originally wired and will disable the Module by shorting the points/condenser junction to Ground. This is typical OEM configuration and no change is required to use the original kill/key switch with this module. Disconnecting the 12V power from the module also works as a kill-switch.

NOTE: The OEM kill-switch only stops the input signal to the Module, it does not automatically disconnect the 12V battery, so a separate 12V power switch is required to remove battery power to the module when not in use.

Restoring back to 100% OEM Magneto type ignition is as simple as removing the module & battery. Re-connect / solder the magneto source coil wire & condenser to the points junction. Replace the original points/condenser type spark-plug coil and your engine is 100% OEM stock ignition again.

Single / Twin Cylinder Applications:

The Module has 2 input wires for the breaker-points signal and One coil output. For 1-cylinder applications the unused TRIGGER wires is grounded.

A 1-cyl application can use a single coil. The twin-coil selected must have 2 high-tension leads for the 2-cyl application (see coil suggestions).

On Single (1-cyl) cylinder installations, only one of the Module Trigger input (WHITE) wires is used (no difference which one is selected), the other (WHITE) trigger input wire is grounded when not used.

TYPICAL SINGLE CYLINDER CONFIGURATION

CONNECTION OF FIREPLUG CDI CONVERSION MODULE

TO EXISTING MAGNETO SYSTEM

FIREPLUG CDI CONVERSION MODULE SPECIFICATIONS:

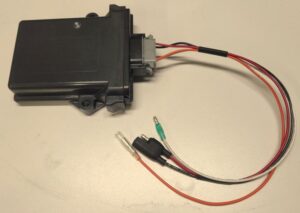

DESCRIPTION: Points & Condenser to CDI conversion Ignition Module

MANUFACTURE: HewTech Electronics LLC, China, MI

INDICATOR: Power ON, Red LED indicator flashes 2X on power-up

APPLICATIONS: Single (1) or Twin (2) cylinder, 2 or 4 cycle internal combustion engines. Snowmobile, Motorcycles, ATV’s, Garden tractors

VOLTAGE: 9VDC to 16VDC

CURRENT: IDLE = 0.5 AMPS MAX RPM = 1.4 AMPS

SPARK OUTPUT: 82mJ @ 12.8VDC

COIL VOLTAGE: 310 Volt DC @ 288HZ

OPERATING RPM: 1-10,000 RPM

TEMPERATURE: -40C to +70C / -40*F to +158*F

IP ENCLOSURE RATING: IP64 (Protected from dust ingress and water spray from any direction)

WARRANTY: This module has a 1-year warranty against defects and workmanship. Any damage that may occur to the module from misuse or other issues is not covered by warranty, and will be evaluated for cost once returned for repair.